PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

ASTM A615 Reinforcement Bar Grade 80

Unlike the former two kinds, ASTM A615 is a deformed steel standard categorized under American standards. These are generally available in diameter between 9.5 mm and 43 mm, and length between 6 m and 12 m. Generally, the steel bars that fall under this standard are under deformed or plain carbon steel. The grades that fall within this standard are Grade 40, Grade 60, Grade 75, and Grade 80.

VIEW MORE +

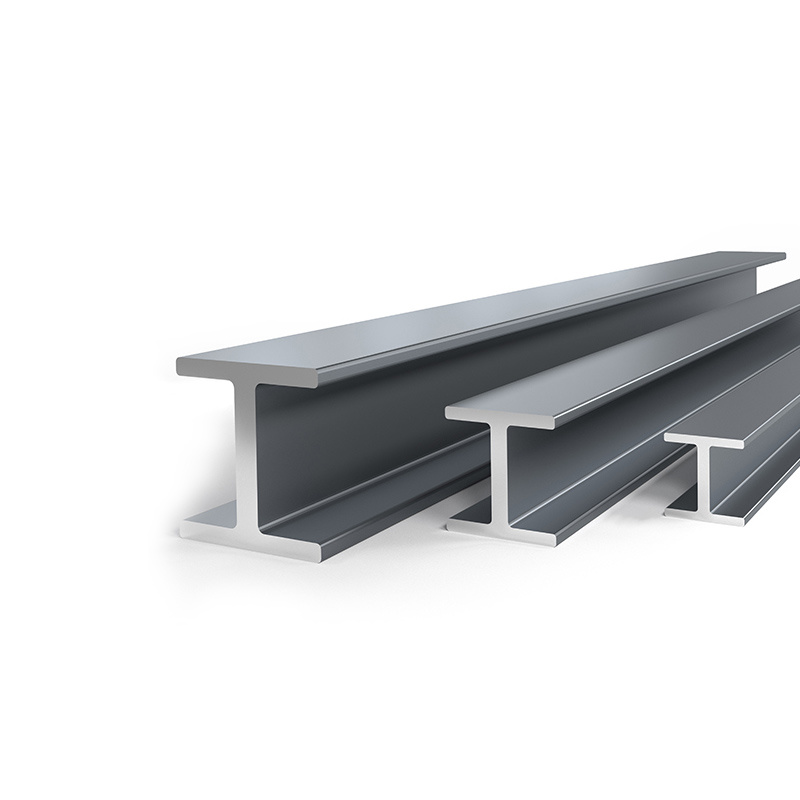

H-beam is a more optimized cross-sectional area distribution, more reasonable than the economic section of high-efficiency profiles, because of its section and the English letter "H" the same name. Since all parts of the H-beam are arranged at right angles, the H-beam has the advantages of strong bending resistance, simple construction, cost saving and light structure in all directions, and has been widely used.

VIEW MORE +

DIN 17175 is suitable for seamless pipes and is used in the construction of boilers, pipelines, pressure vessels and equipment. The maximum temperature can reach 600 ℃. At the same time, under high pressure, the total stress and related fouling conditions can increase or decrease the temperature limit.

VIEW MORE +

HPB300/HRB335/HRB400/HRB500 Reinforcement

B1499.2-2007 is a European standard steel bar. Generally, GB1499.2-2007 standard deformed steel bars are made using the hot-rolled method, meaning that these are the most common types of deformed steel bars. These are available in different lengths and sizes, all the way from 6 mm in diameter to 50 mm in diameter. When it comes to length, 9 m and 12 m are the common sizes.

VIEW MORE +

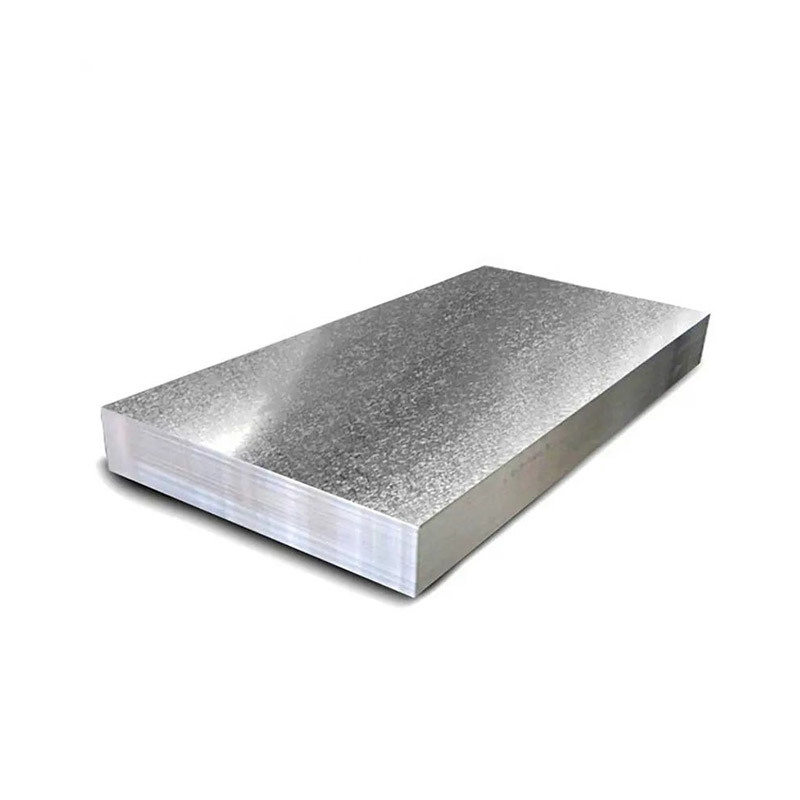

DX53D/ SGCD2/SGCD3 Galvanized Sheet

The material of DX53D galvanized sheet is a non-ferrous alloy composed of zinc as the matrix and adding other elements. The main alloying elements are aluminum, copper, magnesium and so on. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and resistance to atmospheric corrosion.

According to the manufacturing process, it is divided into cast zinc alloy and deformed zinc alloy. The commonly used casting zinc alloy is zinc-aluminum-copper-magnesium alloy, which has good casting process performance, and the cooling rate has little effect on the mechanical properties. They are mainly used in the manufacture of mechanical parts, toys, decorations and household appliances.

VIEW MORE +

EN8/EN9 En Series Carbon Steel Bar

En-8 (1040) It is an unalloyed medium carbon steel with reasonable tensile strength. It is usually supplied in a cold drawn or rolled state. Tensile properties may vary, but are usually between 500 - 800 N/mm. It is widely used in applications that require better performance than mild steel but cannot justify the cost of alloy steel. EN8 can be flame or induction hardened to produce good surface hardness and moderate wear resistance.

VIEW MORE +