A533 Pressure Vessel Carbon Steel Coil

Classification :

A533 Pressure Vessel Carbon Steel Coil Description

ASTM A533 Boiler Vessel Coil is a manganese-molybdenum and manganese-molybdenum-nickel alloy steel coil suitable for welding pressure vessels. Often with quenching and tempering heat treatment, that is, quenching and tempering state supply. ASTM A533 boiler vessel steel is available in five different strength grades: Class A, Class B, Class C, Class D, and Class E. There are three levels of each category: level 1, level 2 and level 3.

Product Parameters

|

Product Name |

A533 Pressure Vessel Carbon Steel Coil |

|

Production Process |

Hot Rolling, Cold Rolling |

|

Material Standards |

AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

|

Width |

45mm-2200mm |

|

Length |

Custom Size |

|

Thickness |

Hot Rolling: 2.75mm-100mm |

|

Delivery Conditions |

Rolling, Annealing, Quenching, Tempered or Standard |

|

Surface Process |

Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

|

A533 |

|

Class A |

Class B |

Class C |

Class D |

Class E |

|

C |

|

0.25 |

0.25 |

0.25 |

0.25 |

0.20 |

|

Mn |

Smelting Analysis |

1.15~1.50 |

1.15~1.50 |

1.15~1.50 |

1.15~1.50 |

1.15~1.70 |

| Finished Product Analysis |

1.07~1.62 |

1.07~1.62 |

1.07~1.62 |

1.07~1.62 |

1.04~1.84 |

|

|

P |

|

0.025 |

0.025 |

0.025 |

0.025 |

0.020 |

|

S |

|

0.025 |

0.025 |

0.025 |

0.025 |

0.015 |

|

Si |

Smelting Analysis |

0.15~0.40 |

0.15~0.40 |

0.15~0.40 |

0.15~0.40 |

0.15~0.40 |

| Finished Product Analysis |

0.13~0.45 |

0.13~0.45 |

0.13~0.45 |

0.13~0.45 |

0.13~0.45 |

|

|

Mo |

Smelting Analysis |

0.45~0.60 |

0.45~0.60 |

0.45~0.60 |

0.45~0.60 |

0.25~0.60 |

| Finished Product Analysis |

0.41~0.64 |

0.41~0.64 |

0.41~0.64 |

0.41~0.64 |

0.21~0.64 |

|

|

Ni |

Smelting Analysis |

… |

0.40~0.70 |

0.70~1.00 |

0.20~0.40 |

0.60~1.00 |

| Finished Product Analysis |

… |

0.37~0.73 |

0.67~1.03 |

0.17~0.43 |

0.57~1.03 |

|

|

Cr |

Smelting Analysis |

… |

… |

… |

… |

0.60 |

| Finished Product Analysis |

… |

… |

… |

… |

0.64 |

Mechanical Properties

|

A533 |

Tensile Strength Ksi(MPa) |

Yield Strength Ksi(MPa) |

Elongation,Gauge Length2 in.[50mm],% |

|

Grade1 |

80-100[550~690] |

50[345] |

18 |

|

Grade2 |

90-115[620~795] |

70[485] |

16 |

|

Grade3 |

100-125[690~860] |

83[570] |

16 |

Physical Performance

|

Physical Performance |

Metric |

Imperial |

|

Density |

7.7-8.03 g/cm3 |

0.278-0.290 lb/in3 |

Scope of Application

ASTM A533 boiler vessel plate has excellent low temperature impact toughness and mechanical properties, and is usually used under low temperature conditions. ASTM A533 boiler vessel plate is widely used in low temperature separation processing, liquefied gas storage and other fields, such as large vacuum low temperature liquefied natural gas (LNG) storage equipment.

|

中国 |

美国 |

德国 |

日本 |

法国 |

英国 |

国际 |

|

GB3077 |

AlSI |

DIN |

JIS |

NE |

BS |

ISO |

|

20Mn2 |

1320 1221 |

20Mn5 |

SMn21 |

20M5 |

150M19 |

- |

|

30Mn2 |

1330 |

30Mn5 |

SMn24 |

32M5 |

150M28 |

- |

|

35Mn2 |

1335 |

36Mn5 |

SMnl |

35M5 |

150M36 |

- |

|

40Mn2 |

1340 1341 |

- |

SMn2 |

40M5 |

- |

- |

|

45Mn2 |

1345 |

46Mn7 |

SMn3 |

45M5 |

- |

- |

|

50Mn2 |

1052 |

50Mn7 |

- |

55M5 |

- |

- |

|

20MnV |

- |

20MnV6 |

- |

|

- |

- |

|

30Mn2MoW |

- |

-- |

- |

|

- |

- |

|

27SiMn |

- |

27MnSi5 |

- |

|

- |

- |

|

35SiMn |

- |

37MnSi5 |

- |

38MS5 |

- |

- |

|

42SiMn |

- |

38MnSi4 46MnSi4 |

- |

38MS5 |

- |

- |

|

20SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

25SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

37SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

40B |

14B35 |

35B2 |

- |

- |

- |

- |

|

45B |

50B46H |

45B2 |

- |

- |

- |

- |

|

50B |

14B50 |

- |

- |

- |

- |

- |

|

4OM∏B |

15B41 |

- |

- |

- |

- |

- |

|

45MnB |

15B48 50B44 |

- |

- |

- |

- |

- |

|

20Mn2B |

- |

- |

- |

- |

- |

- |

|

20MnMoB |

80B20 |

- |

- |

- |

- |

- |

|

15MnVB |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

20MnVB |

- |

- |

- |

- |

- |

- |

|

40MnVB |

- |

- |

- |

- |

- |

- |

|

20MnTiB |

- |

- |

- |

- |

- |

- |

|

25MnTiBRE |

- |

- |

- |

- |

- |

- |

|

2OSiMnVB |

- |

- |

- |

- |

- |

- |

|

15Cr |

5015 5115 |

15Cr3 |

SCr21 |

12C3 |

523A14 523M15 |

- |

|

15CrA |

- |

- |

- |

- |

- |

- |

|

20Cr |

5120 |

20Cr4 |

SCr22 |

18C3 18C4 |

527A19 527M20 |

683/11 20Cr4 20CrS4 |

|

30Cr |

5130 |

28Cr4 |

SCr2 |

28C4 32C4 |

530A30 530A32 |

- |

|

35Cr |

5135 |

34Cr4 37Cr4 |

SCr3 |

38C4 |

530A36 |

683/8 3、 3a、 3b |

|

40Cr |

5140 |

38Cr4 41Cr4 |

SCr4 |

42C4 |

530A40 530M40 |

683/1 4、 4a^ 4b |

|

45Cr |

5145 |

42Cr4 |

SCR5 |

45C4 |

- |

- |

|

50Cr |

5150 5152 |

- |

- |

50C4 |

En48 |

- |

|

38CrSi |

- |

- |

- |

- |

- |

- |

|

12CrMo |

4119 |

13CrMo44 |

- |

12CD4 15CD2 |

- |

- |

|

15CrMo |

ASTM A-387Gr. B |

15CrMo5 16CrMo44 |

SCM21 |

15CD4. 05 |

BS1653 |

- |

|

20CrMo |

4118 |

20CrMo5 22CrMo4 |

SCM22 |

18CD4 20CD4 |

CDS 12 CDSllO |

- |

|

30CrMo |

4130 |

25CrMo4 |

SCM2 |

30CD4 |

CDS 13 |

- |

|

30CrMoA |

- |

32CrMol2 3ICRMo12 |

- |

- |

- |

- |

|

35CrMo |

4135 4137 |

34CrMo4 35CrMo4 |

SCM3 |

35CD4 |

78A37 |

683/1 C35ea C35eb |

|

42CrMo |

4140 4142 |

41CrMo4 42CrMo4 |

SCM4 |

40CD4 42CD4 |

708M40 708A42 709M40 |

683/1 3 |

|

12CrMoV |

- |

- |

- |

- |

- |

- |

|

35CrMoV |

- |

35CrMoV5 |

- |

- |

- |

- |

|

12CrlMoV |

- |

13CrMoV4.2 |

- |

- |

- |

- |

|

25Cr2MoVA |

- |

24CrMoV5.5 |

- |

- |

- |

- |

|

25Cr2MolVA |

- |

- |

- |

- |

- |

- |

|

20CR3MoWVA |

- |

21CrVMoW12 |

- |

- |

- |

- |

|

38CrMoΛl |

6370 (ΛMS) |

34CrAlMo5 41CrAlMo7 |

SACM645 |

40CAD6.12 |

905M39 |

683/10 41CrAlMo74 |

|

20CrV |

6120 |

22CrV4 |

- |

22CrV4 |

- |

- |

|

40CrV |

6140 |

42CrV |

- |

42CrV4 |

- |

- |

|

50CrVA |

6150 |

50CrV4 |

SUPlO |

50CV4 |

735A50 |

- |

|

15CrMn |

- |

16MnCr5 |

- |

16MC5 |

- |

- |

|

20CrMn |

5120 |

20MnCr5 |

SMC21 |

20MC5 |

- |

- |

|

40CrMn |

5140 |

- |

SMC3 |

- |

- |

- |

|

20CrMnSi |

- |

- |

|

- |

- |

- |

|

25CrMnSi |

- |

- |

SMKl |

- |

- |

- |

|

30CrMnSi |

- |

- |

- |

- |

- |

- |

|

30CrMnSiA |

- |

- |

- |

- |

- |

- |

|

35CrMnSiA |

- |

- |

SMK2 |

- |

- |

- |

|

20CrMnMo |

4119 |

20CrMo5 |

SCM23 |

- |

- |

- |

|

40CrMnMo |

4140 |

- |

- |

- |

- |

- |

|

20CrMnTi |

- |

- |

SMK22 |

- |

- |

- |

|

30CrMnTi |

- |

30MnCrTi4 |

- |

- |

- |

- |

|

20CrNi |

3120 |

20NiCr6 |

- |

20NC6 |

637A16 637M17 |

- |

|

40CrNi |

3140 |

46NiCr6 |

SNCl |

35NC6 |

640A35 640M40 |

- |

|

45CrNi |

3145 |

45NiCr6 |

- |

- |

- |

- |

|

50CrNi |

3150 |

- |

- |

- |

- |

- |

|

12CrNi2 |

3115 |

14NiCrlO |

SNC21 |

IONCll 14NC11 |

- |

- |

|

12CrNi3 |

3310 |

13NiCrl2 |

SNC22 |

10NC12 14NC12 |

655A12 655M13 |

- |

|

20CrNi3 |

- |

22NiCrl4 |

- |

20NC11 |

- |

- |

|

30CrNi3 |

- |

28NiCrlO 31NiCrl4 |

SNC2 |

30NC11 30NC12 |

- |

- |

|

37CrNi3 |

- |

35NiCrl8 |

SNC3 |

35NC15 |

- |

- |

|

12Cr2Ni4 |

E3310 |

14NiCrl8 |

- |

12NC15 |

- |

- |

|

20Cr2Ni4 |

E3316 |

22NiCrl4 |

- |

20NC14 |

659A15 659M15 |

- |

|

20CrNiMo |

8620 8720 |

20NiCrMo2 21NiCrMo2 |

- |

20NCD2 |

805A20 805M20 |

- |

|

40CrNiMoA |

4340 9840 |

36NiCrMo4 40NiCrMo6 |

SNCM8 |

35NCD5 40NCD3 |

817M40 816M40 |

- |

|

45CrNiMoVA |

4437 |

- |

SNCM9 |

- |

- |

- |

|

18Cr2Ni4WA |

|

|

|

|

|

|

|

25Cr2Ni4WA |

|

|

|

|

|

|

Factory Appearance

We are a manufacturer and exporter specialized in the research, production, retail, wholesale, packaging, after-sales of metal materials. We have been engaged in export trade for more than 10 years and have rich experience in this field.

Packing and shipping

Our geographical location has convenient transportation, developed logistics, and professional logistics and shipping. We provide customers with convenient, cost-reducing, and value-added services; we have won the recognition and trust of many customers.

Application Areas

Products are widely used in precision instruments, aviation, ships, automobiles, medical, construction, Bridges, boilers, parts processing and other industries.

Customer Visit

The products distributed by our company are guaranteed by the manufacturer, and have a complete pre-sale, in-sale and after-sales service system. Our company has a strong standing stock of thousands of tons, sufficient supply and complete specifications. It has formed an annual inventory turnover of more than 10,000 tons and more than 900 specifications.

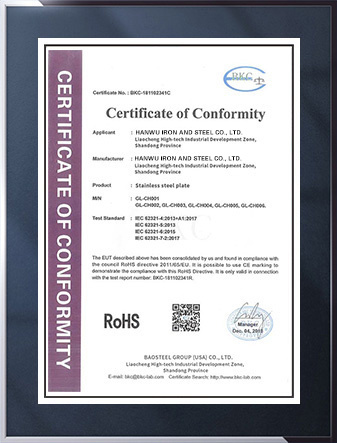

HONOR

RELATED PRODUCTS

GET A FREE QUOTE