Galvanized I-Steel

Classification :

Product Description

Hot-dip galvanized I-steel is also called hot-dip galvanized I-steel or hot-dip galvanized I-steel. It is to immerse the I-beam after derusting into molten zinc at about 500 ℃ to attach a zinc layer to the surface of the I-beam, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs.

Product Parameters

|

Material |

A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

|

Scope of production |

H100*100-H400*400H150*75 -H900*300 |

|

Length |

6m, 9m, 12mor according to customer requirements |

|

Technology |

Hot rolled, welded |

|

Standard |

ASTM,AISI,JIS,GB, DIN,EN |

|

Surface |

Galvanized, painted;or according to your requirements |

|

supply capacity |

2000tons/Day |

|

Business Type |

Manufacturer |

|

Certificate |

ISO, SGS,BV |

|

Application |

Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

|

loading port |

Any port in China |

|

Packaging |

Standard export packing or as your request |

|

Payment Method |

Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

|

符号: h—高度; b—宽度; tw—腹板厚度; t—翼缘平均厚度; I—惯性矩; W—截面模量 |

|

i— 回转半径; Sx—半截面的面积矩; 长度: 型号 10~18,长 5~19m; 型号 20~63,长 6~19m。 |

|||||||||||||

|

|

尺 寸(mm) |

截面面积 (cm2) |

理论重量 (kg/m) |

x-x 轴 |

y-y 轴 |

||||||||||

|

|

h mm |

b mm |

tw mm |

t mm |

R mm |

|

|

Ix cm4 |

Wx cm3 |

ix cm |

Ix/Sx cm |

Iy cm4 |

Wy cm3 |

Iy cm |

|

|

10 |

100 |

68 |

4.5 |

7.6 |

6.5 |

14.3 |

11.2 |

245 |

49 |

4.14 |

8.69 |

33 |

9.6 |

1.51 |

|

|

12.6 |

126 |

74 |

5 |

8.4 |

7 |

18.1 |

14.2 |

488 |

77 |

5.19 |

11 |

47 |

12.7 |

1.61 |

|

|

14 |

140 |

80 |

5.5 |

9.1 |

7.5 |

21.5 |

16.9 |

712 |

102 |

5.75 |

12.2 |

64 |

16.1 |

1.73 |

|

|

16 |

160 |

88 |

6 |

9.9 |

8 |

26.1 |

20.5 |

1127 |

141 |

6.57 |

13.9 |

93 |

21.1 |

1.89 |

|

|

18 |

180 |

94 |

6.5 |

10.7 |

8.5 |

30.7 |

24.1 |

1699 |

185 |

7.37 |

15.4 |

123 |

26.2 |

2.00 |

|

|

20 |

a |

200 |

100 |

7 |

11.4 |

9 |

35.5 |

27.9 |

2369 |

237 |

8.16 |

17.4 |

158 |

31.6 |

2.11 |

|

|

b |

|

102 |

9 |

|

|

39.5 |

31.1 |

2502 |

250 |

7.95 |

17.1 |

169 |

33.1 |

2.07 |

|

22 |

a |

220 |

110 |

7.5 |

12.3 |

9.5 |

42.1 |

33 |

3406 |

310 |

8.99 |

19.2 |

226 |

41.1 |

2.32 |

|

|

b |

|

112 |

9.5 |

|

|

46.5 |

36.5 |

3583 |

326 |

8.78 |

18.9 |

240 |

42.9 |

2.27 |

|

25 |

a |

250 |

116 |

8 |

13 |

10 |

48.5 |

38.1 |

5017 |

401 |

10.2 |

21.7 |

280 |

48.4 |

2.4 |

|

|

b |

|

118 |

10 |

|

|

53.5 |

42 |

5278 |

422 |

9.93 |

21.4 |

297 |

50.4 |

2.36 |

|

28 |

a |

280 |

122 |

8.5 |

13.7 |

10.5 |

55.4 |

43.5 |

7115 |

508 |

11.3 |

24.3 |

344 |

56.4 |

2.49 |

|

|

b |

|

124 |

10.5 |

|

|

61 |

47.9 |

7481 |

534 |

11.1 |

24 |

364 |

58.7 |

2.44 |

|

32 |

a |

320 |

130 |

9.5 |

15 |

11.5 |

67.1 |

52.7 |

11080 |

692 |

12.8 |

27.7 |

459 |

70.6 |

2.62 |

|

|

b |

|

132 |

11.5 |

|

|

73.5 |

57.7 |

11626 |

727 |

12.6 |

27.3 |

484 |

73.3 |

2.57 |

|

|

c |

|

134 |

13.5 |

|

|

79.9 |

62.7 |

12173 |

761 |

12.3 |

26.9 |

510 |

76.1 |

2.53 |

|

36 |

a |

360 |

136 |

10 |

15.8 |

12 |

76.4 |

60 |

15796 |

878 |

14.4 |

31 |

555 |

81.6 |

2.69 |

|

|

b |

|

138 |

12 |

|

|

83.6 |

65.6 |

16574 |

921 |

14.1 |

30.6 |

584 |

84.6 |

2.64 |

|

|

c |

|

140 |

14 |

|

|

90.8 |

71.3 |

17351 |

964 |

13.8 |

30.2 |

614 |

87.7 |

2.6 |

|

40

|

a |

400 |

142 |

10.5 |

16.5 |

12.5 |

86.1 |

67.6 |

21714 |

1086 |

15.9 |

34.4 |

660 |

92.9 |

2.77 |

|

|

b |

|

144 |

12.5 |

|

|

94.1 |

73.8 |

22781 |

1139 |

15.6 |

33.9 |

693 |

96.2 |

2.71 |

|

|

c |

|

146 |

14.5 |

|

|

102 |

80.1 |

23847 |

1192 |

15.3 |

33.5 |

727 |

99.7 |

2.67 |

|

45 |

a |

450 |

150 |

11.5 |

18 |

13.5 |

102 |

80.4 |

32241 |

1433 |

17.7 |

38.5 |

855 |

114 |

2.89 |

|

|

b |

|

152 |

13.5 |

|

|

111 |

87.4 |

33759 |

1500 |

17.4 |

38.1 |

895 |

118 |

2.84 |

|

|

c |

|

154 |

15.5 |

|

|

120 |

94.5 |

35278 |

1568 |

17.1 |

37.6 |

938 |

122 |

2.79 |

|

50

|

a |

500 |

158 |

12 |

20 |

14 |

119 |

93.6 |

46472 |

1859 |

19.7 |

42.9 |

1122 |

142 |

3.07 |

|

|

b |

|

160 |

14 |

|

|

129 |

101 |

48556 |

1942 |

19.4 |

42.3 |

1171 |

146 |

3.01 |

|

|

c |

|

162 |

16 |

|

|

139 |

109 |

50639 |

2026 |

19.1 |

41.9 |

1224 |

151 |

2.96 |

|

56 |

a |

560 |

166 |

12.5 |

21 |

14.5 |

135 |

106 |

65576 |

2342 |

22 |

47.9 |

1366 |

165 |

3.18 |

|

|

b |

|

168 |

14.5 |

|

|

147 |

115 |

68503 |

2447 |

21.6 |

47.3 |

1424 |

170 |

3.12 |

|

|

c |

|

170 |

16.5 |

|

|

158 |

124 |

71430 |

2551 |

21.3 |

46.8 |

1485 |

175 |

3.07 |

|

63

|

a |

630 |

176 |

13 |

22 |

15 |

155 |

122 |

94004 |

2984 |

24.7 |

53.8 |

1702 |

194 |

3.32 |

|

|

b |

|

178 |

15 |

|

|

167 |

131 |

98171 |

3117 |

24.2 |

53.2 |

1771 |

199 |

3.25 |

|

|

c |

|

780 |

17 |

|

|

180 |

141 |

102339 |

3249 |

23.9 |

52.6 |

1842 |

205 |

3.2 |

Factory Appearance

We are a manufacturer and exporter specialized in the research, production, retail, wholesale, packaging, after-sales of metal materials. We have been engaged in export trade for more than 10 years and have rich experience in this field.

Packing and shipping

Our geographical location has convenient transportation, developed logistics, and professional logistics and shipping. We provide customers with convenient, cost-reducing, and value-added services; we have won the recognition and trust of many customers.

Application Areas

Products are widely used in precision instruments, aviation, ships, automobiles, medical, construction, Bridges, boilers, parts processing and other industries.

Customer Visit

The products distributed by our company are guaranteed by the manufacturer, and have a complete pre-sale, in-sale and after-sales service system. Our company has a strong standing stock of thousands of tons, sufficient supply and complete specifications. It has formed an annual inventory turnover of more than 10,000 tons and more than 900 specifications.

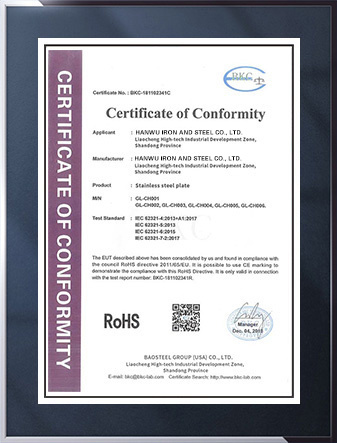

HONOR

RELATED PRODUCTS

GET A FREE QUOTE